HS2 Ltd has announced it will be using retired wind turbine blades originally destined for the incinerator to make reinforced concrete that is carbon-friendly.

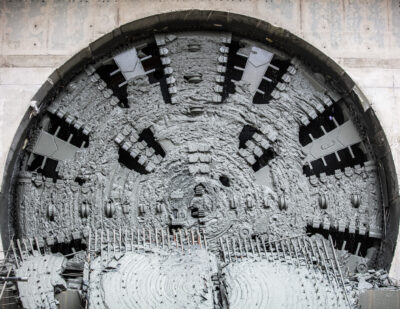

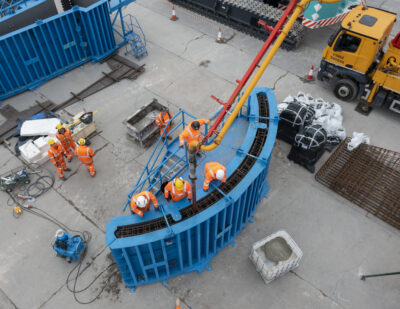

It says the process will cut carbon production by up to 90 percent. The traditional method would make use of rebar. However, in this pilot project, that rebar will be swapped for sections of glass fibre reinforced polymer turbine blades that are no longer being used for generating electricity.

Estimates suggest around 15,000 turbine blades are to be decommissioned in the United Kingdom and European Union by 2023. Up until now such blades have been ground down and used as a building material, or sent to incinerators.

By using the decommissioned blades, a 90 percent carbon saving will be made in the production of the concrete reinforcement.

The project is being delivered by Skanska Costain STRABAG joint venture and the National Composites Centre.

“Reusing old turbine blades reduces waste, cuts demand for new steel and reduces the carbon generated during the production of concrete.

“This scheme is a brilliant example of the innovation happening on the whole HS2 project. If our world-first pilot project goes well, we could see a waste product from the energy industry becoming an essential material for the construction sector in the future.”

This method is thought to be a world-first. As such, reuse will initially focus on exchanging steel for turbine blades in low-stress structures, e.g. temporary access roads, top sections of concrete walls and ground-bearing plinths, e.g. on which portacabins might be erected.

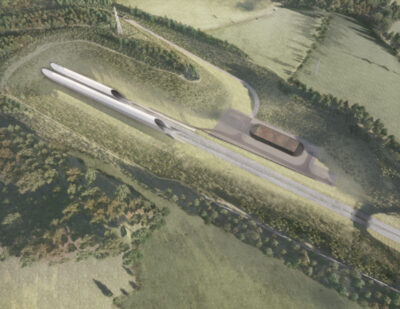

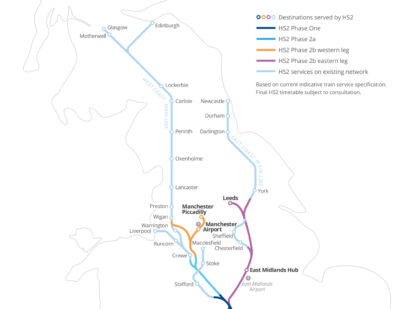

Work on the proof of concept pilot is due to start in spring. Should it be successful, it could be followed by a full roll out consisting of HS2’s London tunnels between the M25 motorway and Euston station.

“Wind turbine blades are extremely difficult to recycle. Ideas of what to do with them after they’re taken down range from turning them into playground slides to processing them into pellets for glues and paints.

“What’s potentially so significant about this innovation is that unlike some other turbine blade recycling initiatives, which involve reprocessing, our innovation reinforces concrete with sections simply cut from the turbines – massively reducing the carbon produced in repurposing the blades.”